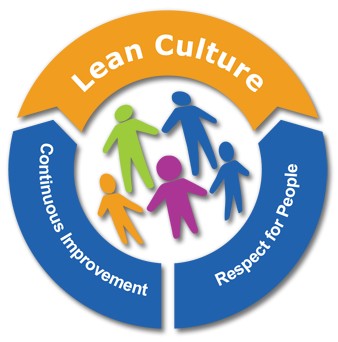

Today I will discuss how a company can sustain a lean culture once they have implemented lean practices in order to achieve continuous improvement. Your company has started the lean journey, but how do you sustain it? I use a method I call managing for daily improvement or MDI. Let’s first talk about first setting the stage, then give you practical practices and tactics to achieve a sustainable lean culture, and then provide core key performance indicators (KPIs) to track your progress. As a lean professional for many decades, let me be your guide to not only implementing lean, but truly creating an adoption of lean and a lean culture.

How can we Continuously Improve Daily and Sustain a Lean Culture and Behavior?

First and foremost, look to your people, the best resource you have. These people touch every part of daily operations through a process called managing by DAILY improvement (MDI). When a Lean culture is truly developed in a company, and old behavior, habits, and ways of working are modified, people become process improvement and problem solvers. These people/teams believe that there is always a better way to do anything.

The focus is to eliminate all wastes in the organization, improve processes, solve root cause problems, create a pull environment, and ensure that Lean Six Sigma (LSS) works for quality and daily problem solving using DMAIC (Define, Measure, Analyze, Improve, and Control) and PDCA (Plan, Do, Check, and Act).

Why are we doing this? The focus is to bring value to the customer, beyond the customers’ expectations. How do we monitor what our customers feel about us? What are our pros/cons? You use a Voice of the Customer (VoC) survey to obtain negatives and positives from your customers. You should also use the Voice of your Employees (VoE) to ask your teams what can be done to improve your operations: both your external and internal customers. Use Pareto’s 80/20 principle to prioritize both negative and positive feedback from your customers and employees and continuously improve daily based on this data.

Visual management and KPIs are a necessity in Managing for Daily Improvement for people on the shop floor. Don’t you feel individuals want to do well? Instead of the typical top-down approach, MDI fosters bottom-up, continuous, daily processing change. People then share experiences with each other in daily cross-functional Lean teams.

These teams and people meet daily in a “huddle” to discuss previous day goals and actual results. These teams can identify the root causes that created missing reaching their goals and determine a time frame for completion. Then, the team assigns responsibility for the action required to reach the desired solution. All activities are documented by a team recorder. MDI allows for those challenges that cannot be quickly resolved to be escalated. Leadership then commits to solve this problem. This increases employee morale.

Lean by Creating “Standard Work”

In order to create and sustain a Lean culture, each step in the process should be defined and must be performed repeatedly in the same manner. Any variations in the process will most likely increase cycle time and cause quality issues. It typically describes how a process should consistently be executed and documents current ‘best practices.’ It provides a baseline from which a better approach can be developed, allowing continuous improvement methods to leverage learning. Three necessary components in standard work are (1) takt time, (2) cycle time and (3) SWIP (Standard Work-in-Progress).

(1) takt time, (2) cycle time and (3) SWIP (Standard Work-in-Progress).

(2) cycle time and (3) SWIP (Standard Work-in-Progress).

(3) SWIP (Standard Work-in-Progress).

Developing Standard Work is one of the more difficult Lean Six Sigma disciplines; however, if efficiently developed, it should allow virtually anyone to perform the work without any variance in the desired output.

MDI improves performance to goals and KPIs and EMPOWERS employees to effect change from the ground level at Gemba up.

Gemba walks help a great deal. Leadership can’t just sit in “executive row”, but rather come to Gemba and solve problems/improve processes with the people. The “them versus us” syndrome then becomes WE!

When Lean culture takes hold, the teams are self-managed, managers are no longer reactionary, and they become strategic, proactive thinkers providing sustainable solutions.

How to Breakthrough Lean Culture Plateaus

Like adopting any culture, like a lean culture, often, you find you may hit a plateau. Ask yourself, “Has the Lean team plateaued? Is the team not improving as much? Is the team lacking the motivation to challenge themselves to improve? Are the improvements you implement moving you in many different directions with no focus? Are you collecting a long list of problems but you never get around resolving them?”

There is nothing wrong with these teams being competitive to see which team has the best process or problem solutions monthly. Entering these team projects in a magazine, or Lean contest is a motivator to boost teamwork and ensure that MDI is effective every day. The contest is an answer to the question of how you build and maintain momentum for a Lean journey….that has no end. Celebrate your “wins.” Learn from your losses/mistakes. This competition recognizes your people’s contributions and efforts and keeps the lean culture spirit alive.

At Flextronics in Milpitas, CA, judges from outside of the Flextronics organization also contribute to the nature of Flex’s global lean competition. Lean leaders from Boeing Co, the HNI Corp., NXP Semiconductors and Shingijutsu participate in the competition. They judge the Flex teams, choose a winner, and it is collaborative, as each company learns from each other. Flex calls it “building it’s Lean DNA.” Flex is eight (8) years into its Lean journey.

MDI: The Missing Link in Lean Culture

Managing for Daily Improvement (MDI) is the missing link in lean culture transformation efforts. While Kaizen events and continuous improvement (CI) projects provide breakthrough results, these are often not sustained. The key to sustainment, as well as 100 percent involvement, resides in the power of MDI. Learn the two critical phases of MDI, including:

The power of daily team huddles.

- Using a “Business Status Sheet” to drive daily improvement.

- Leader standard work in order to create accountability within the team structure;

- Problem-solving thinking; how to align your organization so that the right problems are solved at the right level.

MDI is by far the most important tool that drives accountability and problem-solving minute-by-minute, hour-by-hour, and day-by-day.

Teamwork is critical as are the daily huddles.

For a Lean Culture, Understand the Payoff of Behavior Change

In the quest to a lean culture and sustaing that culture, you must understand the outcomes from certain behaviors. Here is what to expect in the behavior and dividends list:

| Behaviors | Dividends |

| Establishes personal Standard Work and makes time for improvement | Replaces firefighting routines with improvement based ones |

| Practices and learns how to apply Lean tools | Can learn to ask the ‘right’ questions to get faster, lasting improvements |

| Develops people in the use of problem-solving skills | Creates a workforce of problem solvers to grow and embed daily improvement |

| Believes there is always a solution for overcoming an obstacle | Creates an environment of ‘how we’ instead of ‘we can’t’ |

| Relies on a skilled workforce to find the solutions | Leverages and builds the collective talent and trust of the team |

| Reflects a positive perspective and learns from previous experiences | Builds a positive ‘attitude reflects leadership’ team environment |

Key Performance Indicators in the Lean Quest

To start you must have the KPI’s visual along the value stream. In order to be daily, the KPIs need to get down to ownership by the workers within the value stream. These metrics would, of course, be aligned and are updated every hour. The metrics are also manual as automatic metric systems cannot retrieve the information at an hourly frequency as these metrics are process inputs and not outputs. For example, if your strategy is to improve Quality, the people in the value stream would own a control chart of heat applied to the product. If heat is known to vary causing defects when special causes arise then you should see an effect on the overall quality (the next level KPI). The key is to identify the process inputs having an effect on the output because this is what the workers can directly control. Of course, you would also have the responsible workers as a team performing Kaizen to eliminate the root causes. Next, you would have management supporting this effort during their daily Gemba walk, reviewing these hourly metrics. They would use STP techniques (Support, Teach, and Promote) to provide daily improvements and momentum towards achieving the strategy. Specific metrics: process metrics and outcome metrics.

Lean is a challenge to implement. Everyone in the company, from Leadership to the shop floor, has to practice Lean thinking to achieve a sustained Lean culture. It is a new way of doing business. It takes years. Once implemented, Lean has to be sustained. Competition is one way to sustain Lean in any company.

Question: Where are you on your Lean journey for a Lean culture?

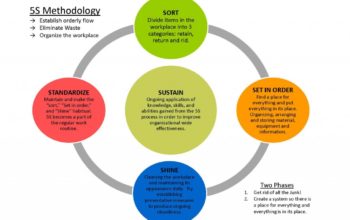

Why not check out our articles on waste reduction and 5s

Lean culture WIKI